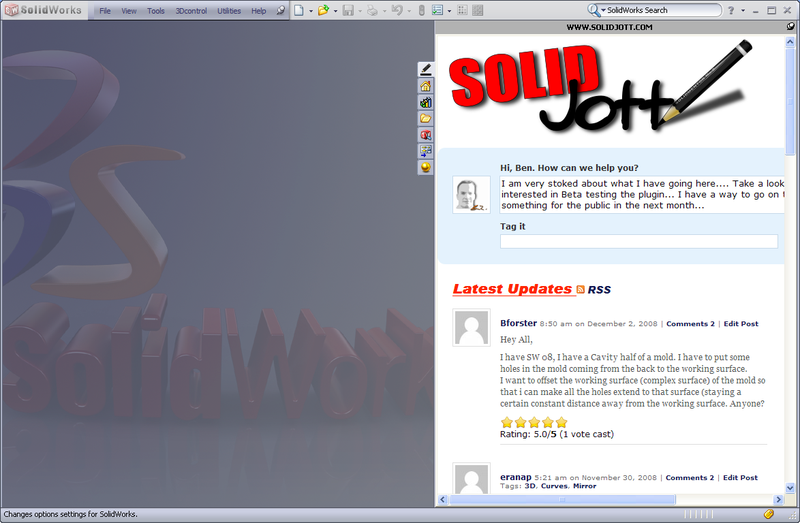

New SolidWorks Help Site – SolidJott!

Our friend Ben Eadie of SolidMentor fame has started a new SolidWorks site called SolidJott. The format is a microblog that anyone can post to (requires a free account) and other users can reply in the comments. You can add tags to your posts/questions so that you can more easily find them later. Anyone using Twitter should feel right at home.

Our friend Ben Eadie of SolidMentor fame has started a new SolidWorks site called SolidJott. The format is a microblog that anyone can post to (requires a free account) and other users can reply in the comments. You can add tags to your posts/questions so that you can more easily find them later. Anyone using Twitter should feel right at home.

There is an RSS feed so that you can get all the posts pushed to you, and Ben is also working on a SolidWorks add-in so that you can post and answer to SolidJott from right within the SolidWorks Task Pane! Be sure to check the SolidJott site for more information, as this add-in will be going into Beta before long.